Portfolio

On all projects Reese Engineering was responsible for: Engineering Design, Specify all components, order components, Fabricate, Assemble, Test, Install. Exceeded expectations, completed on or before 1st specified due date, done at or under estimated budget.

The F450 Slider

I designed, built, and installed the slider mechanism and cable arm assembly that goes under the electronics box.

It is designed to operate in a harsh environment, self latching, and I did the entire thing:

Engineering Design, Specify all components, order components, Fabricate, Assemble,Test, Install on Customer’s vehicle. All in under 2 weeks. Exceeds expectations, done on or under specified budget.

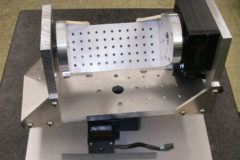

The Elect Part Tester 2012

I designed, and built that test fixture for them.

Repeat part testing, quick part in-out, minimal tool wear, no damage to parts, mechanical one-way part orientation

And it was also quick turn-around: 1-week design, build, deliver, exceeds expectations, done on or under specified budget, delivered on or before expected date.

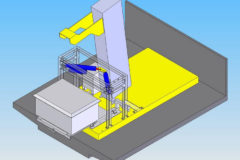

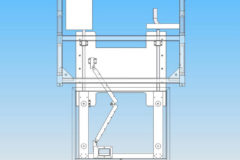

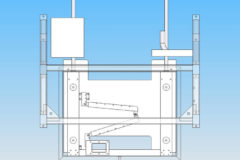

IPT Fret Stacker: – An Automated Project!

That was an automated machine I built for a customer here in town.

For the machine I did the whole thing: Engineering Design, Specify all components, order components, Fabricate, Assemble, Program, Test, Install at Customer’s factory, follow-up, tune, then built 6 more units.

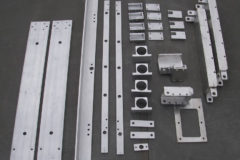

Autoliv

I modified a machine that tests 1 specific type of camera.

They needed it to do 2 different cameras with extreme precision and alignment.

Can not take the existing machine out of production at any time

Any parts that need to be changed on existing machine needed to be made NEW and swapped-out so they could go back to the old machine if necessary.

Time-frame 1-month from green light to required delivery date.

(demanding schedule for this type of modification. normal would be 3~5 months.)

Engineering Design and simulation, fabrication, assembly & testing, 4 hour install, reprogram existing machine’s logic controller for added functionality.

Exceeds expectations, done on or under specified budget, delivered on or before expected date.

CMC Rescue

This was an add-on attachment for an existing computer-controlled sewing machine.

It attached to the machine and enabled them to sew a rope onto a hook.

The hook was held in place on 1 side of the fixture and the rope in the sewing area.

Quick rope and hook in and out of the fixture.

Adjustable tension on the rope to keep it in place but not bind the needle as the sewing takes place.

Engineering Design, Specify all components, order components, Fabricate, Assemble, Test, Install at Customer’s factory.